Tomophan® Phantom

TOMOPHAN® IMAGE QUALITY PHANTOM

If you have not worked extensively with digital breast tomosynthesis (DBT) imaging, you may not be fully aware how different it is from conventional mammography and CT. The Tomophan® phantom has been designed to provide a complete characterization of this unique imaging system through objective measurements of key performance criteria.

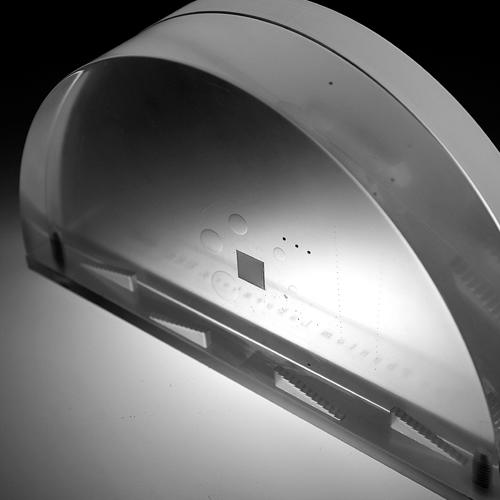

The basic phantom is made from 3 key components: the 28mm test object, the 14mm spacer and the chest wall. For routine testing, the test object and spacer are stacked providing a total thickness of 42mm with the primary test plane in the center. By changing the position of the 14mm uniform spacer and/or flipping the test object, the primary test plane will be moved higher or lower in the imaging field.

To simulate a smaller breast the 28mm test object can be used alone. An optional 28mm spacer can be used with the test object to simulate a 56mm breast.

Smári Image Analysis Service

The Tomophan® is equipped with Smári, a powerful, web-based image analysis service created by The Phantom Laboratory. Smári delivers automated phantom image analysis in the cloud and maintains measurements in a database for trend analysis, machine comparisons, and historical records.

For more details please see the Tomophan® Product Guide and Data Sheet.

Phantom tests include:

Slice width: Using two sets of angled bead ramps the slice thickness and slice sensitivity profile (SSP) can be evaluated.

Slice increment: The bead ramps are also used to provide a slice incrementation measurement.

Z-axis scaling: The phantom contains 1 mm aluminum z-axis beads to evaluate image scaling in the z-axis.

Z-axis uniformity: The phantom is cast from a uniform material and uniformity can be assessed in designated areas away from other test objects.

In-slice signal drop: The in-slice signal drop can be assessed from the bead ramp patterns.

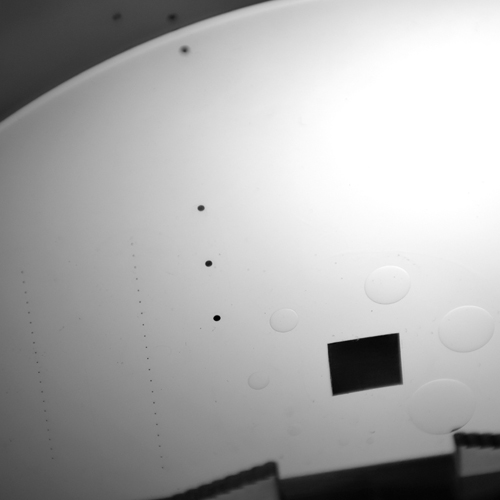

CNR, SNR and NPS: The Tomophan® phantom has a .2mm thick, 1cm square aluminum foil insert. This aluminum square can be used in the calculation of the Contrast to Noise Ratio (CNR).

High resolution MTF in both x and y directions: The edge profile of the aluminum square can be used to calculate the line spread function and the corresponding MTF in both x and y directions.

Regional in-plane uniformity: The phantom is cast from a uniform material. The design sets aside areas to be used in uniformity measurements. The material’s pixel value is designed to be uniform over these local regions. These areas are used for measurements of spatial uniformity, mean pixel number and noise standard deviation values.

Lost chest tissue measurement: Using four stair-stepped chest wall missing tissue gauges a measurement of missing chest wall can be made in two locations along the wall at two different slice heights. The four gauges have 12 steps in 0.5mm increments rising into the phantom from the chest wall.

Pixel size verification: Pixel size can be verified from known geometric feature positions.

Low contrast: The phantom has 8 acrylic spheres located in a central circular pattern. The spheres are used to evaluate the scanner’s low contrast capability.

Phantom Alignment: The phantom includes fiducial objects to confirm the orientation of the phantom.